3D Printing at Cal NERDS

What is 3D Printing?

One way to visualize this process is to think of Legos being placed on top of each other, one layer at a time, slowly building the part up. It’s almost magical watching your design be built from the bottom up and having the ability to create almost any shape your mind can conceive. Today, this technology has never been more accessible. You can buy yourself a robust entry 3D printer for only $200 (as of May 2023) on Amazon!

In this Blog we will learn about the different types of 3D printing, what UC Berkeley is doing with 3D printing, and how you could experience 3D printing here at CAL!

Different types of 3D Printing

Fused Deposition Modeling (FDM)

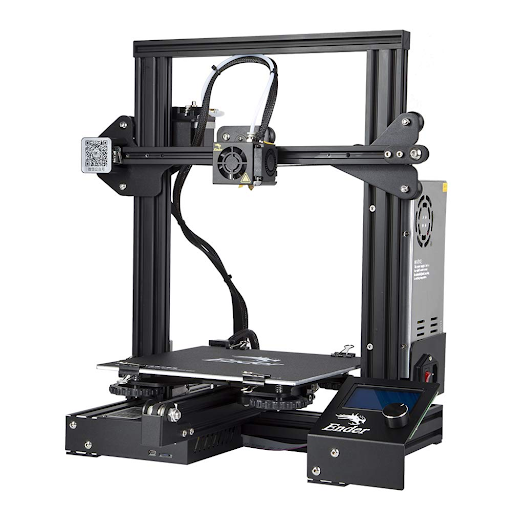

The specific 3D printer I linked above is a type of 3D printing called FDM (Fused Deposition Modeling). FDM is the most widely used type of 3D printing from hobbyists to industrial level companies. It works by extruding thermoplastic filaments, such as ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid), through a heated nozzle, melting the material and applying the plastic layer by layer on a build platform. Each layer is laid down one at a time until the part is complete.

Stereolithography (SLA)

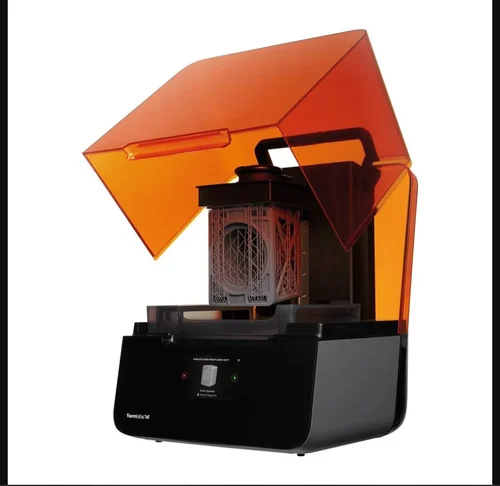

Stereolithography 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization. In addition to FDM 3D printers, SLA resin 3D printers have become popular for their ability to produce high-accuracy parts in a range of materials with fine features and smooth surface finishes.

Resin 3D printing is a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts.

Selective Laser Sintering (SLS)

Selective laser sintering (SLS) 3D printers use a high-power laser to sinter small particles of polymer powder into a solid structure. SLS 3D printers are ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

What UC Berkeley is doing in the 3D Printing world

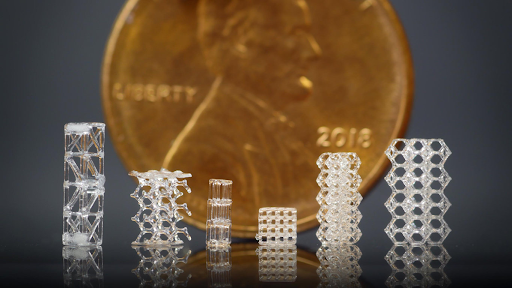

Researchers develop innovative 3D-printing technology for glass microstructures

Researchers at UC Berkeley have developed a new way to 3D print glass microstructures that is faster and produces objects with higher optical quality, design flexibility and strength. They dubbed this new system “micro-CAL.” This process is fundamentally different from today’s industrial 3D-printing manufacturing processes, which build up objects from thin layers of material. This technique can be time-intensive and result in rough surface texture. CAL, however, 3D-prints the entire object simultaneously.

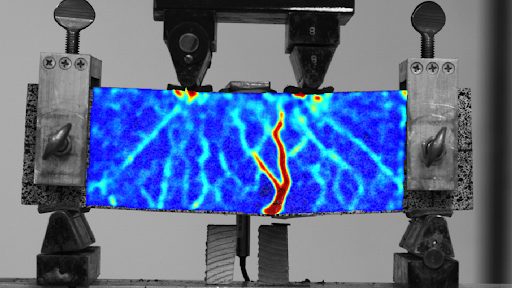

Berkeley researchers use 3D printer to make stronger, greener concrete

Researchers at UC Berkeley have developed a new way to reinforce concrete with a polymer lattice, an advancement that could rival other polymer-based enhancements and improve concrete’s ductility while reducing the material’s carbon emissions.

The Berkeley team used a 3D printer to build octet lattices out of polymer, and then filled them with ultra-high performance concrete (UHPC), which is four times stronger than conventional concrete in compression. The reinforced material performed well in tests of compression and four-point bending.

How You Could Access 3D Printers Here in UC Berkeley

CAL Nerds (FREE Makerspace)

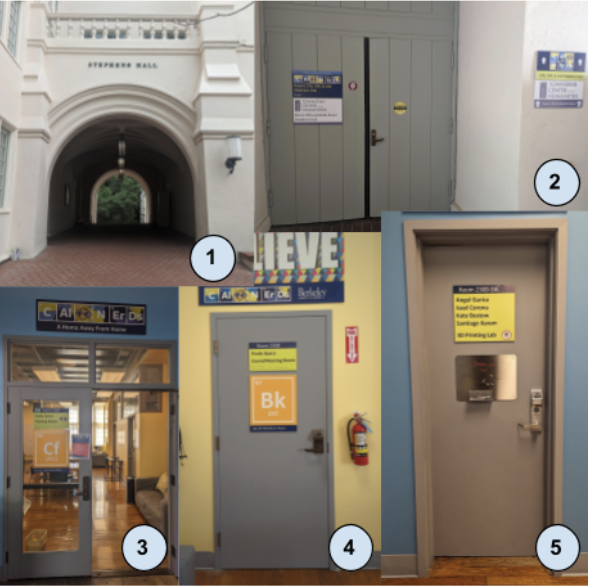

CAL Nerds has their own 3D printing lab that is open to the public! It is located in Stephens Hall 230D-DA (Follow the instructions to find it):

-

First go to Stephens Hall

-

The main entrance is on your right with a CAL Nerds sign

-

Go through the hallway and on your right will be room 230C, the Study Space

-

Immediately look to your left and go into room 230D with a big “BELIEVE” sign above

-

All the way to the back of room 230D will be the 3D printing lab, room 230D-DA

-

And ta-da! You have arrived at the CAL Nerds 3D printing lab!

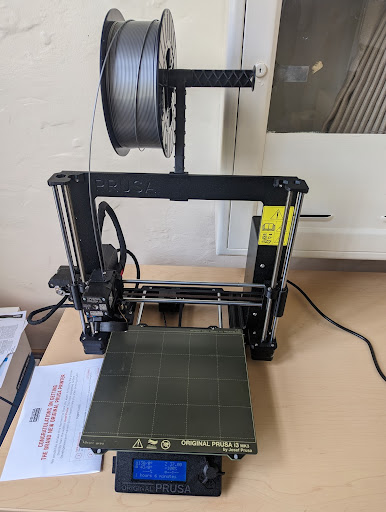

The 3D printing Lab comes equipped with 3 Original Prusa i3 MK3 printers.

Supernode (FREE Makerspace)

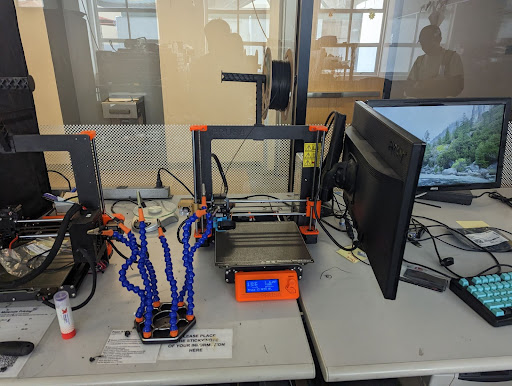

Supernode is a student-run space, and all our equipment (3D printers, soldering irons, and more) will always be free to use to anybody in the UC Berkeley community. The door is open whenever a member is inside.

Supernode is located in 246 Cory Hall, the Chenming Hu Innovation Lab.

3D Printing Decals (FREE Course)

These are 1-2 unit student lead courses called Decals you could take for a whole semester. Keep your eye out for these 3D printing decals:

3D Printing and Design (Fall 2022)

Exploration in Bioprinting (Spring 2023)

JACOBS SELF-SERVICE PRINTING ($$$)

The Jacobs Institute for Design Innovation offers self-service printing. This service allows users to manage their model library, slice models for 3D printing, and remotely send prints to their Ultimaker 3D printer fleet. The only fee one must pay is the material costs.

Follow the website's instructions on how to use their service. Once the print has been sent and finished the user has within 1 week of printing to pick it up at the first-floor patio entrance to Jacobs Hall on the south side during pickup hours.

(Pick up hours: Weekdays 11am – 1pm)

Maker Pass ($$$)

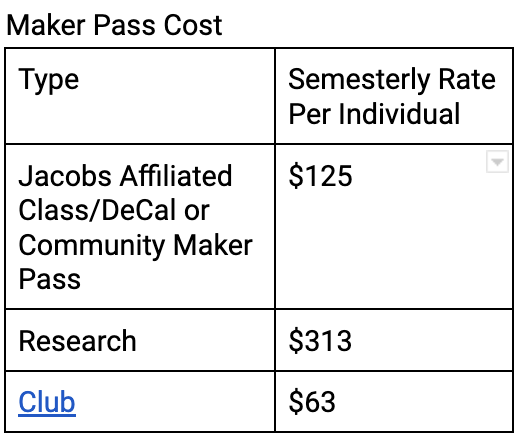

I would suggest you consider purchasing a Maker Pass if you feel comfortable using 3D printers and are passionate about learning and tinkering because it is expensive to purchase one.

Maker passes are available to UC Berkeley students, faculty, and staff, the Maker Pass is a point of entry to hands-on making in Jacobs Hall and the CITRIS Invention Lab. With this semesterly pass, campus community members from all departments can access workspaces and use equipment on a drop-in basis, including during extended access hours (evenings and weekends) at Jacobs Hall.

A Maker Pass cost table is on the right, but if you are eligible it can be waived (Point #3). Additionally, if you join a club, fellowship, or group they may already have Maker Passes they can lend.

A Maker Pass comes with access to workspace and equipment (such as Prusa, Lulzbot, and experimental 3D printers). Also, you have access to Design Specialists, Workshops, and the Jacobs Hall Material Store.